Additive Manufacturing

Solid State Metal 3D Printing

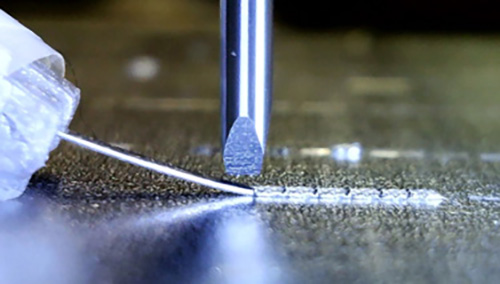

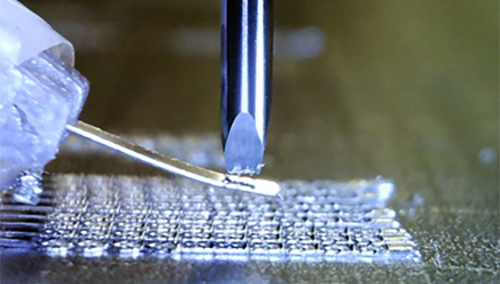

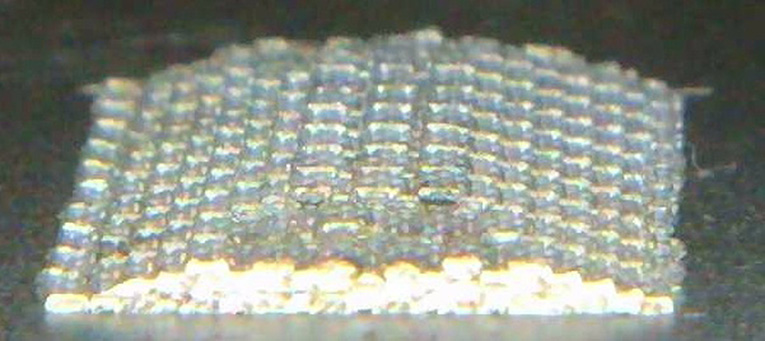

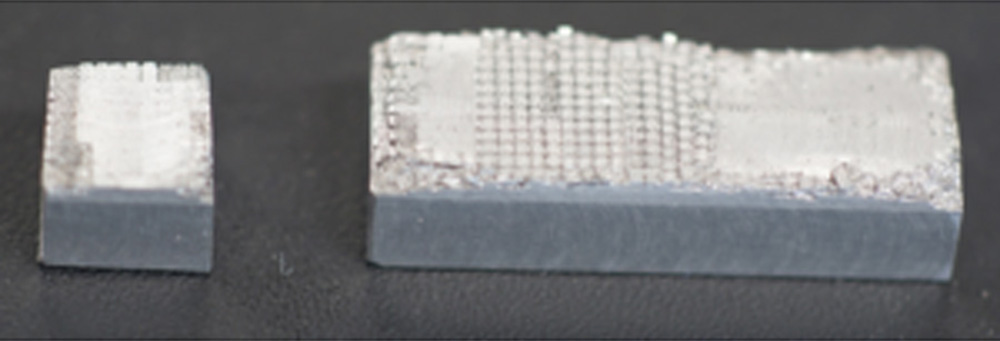

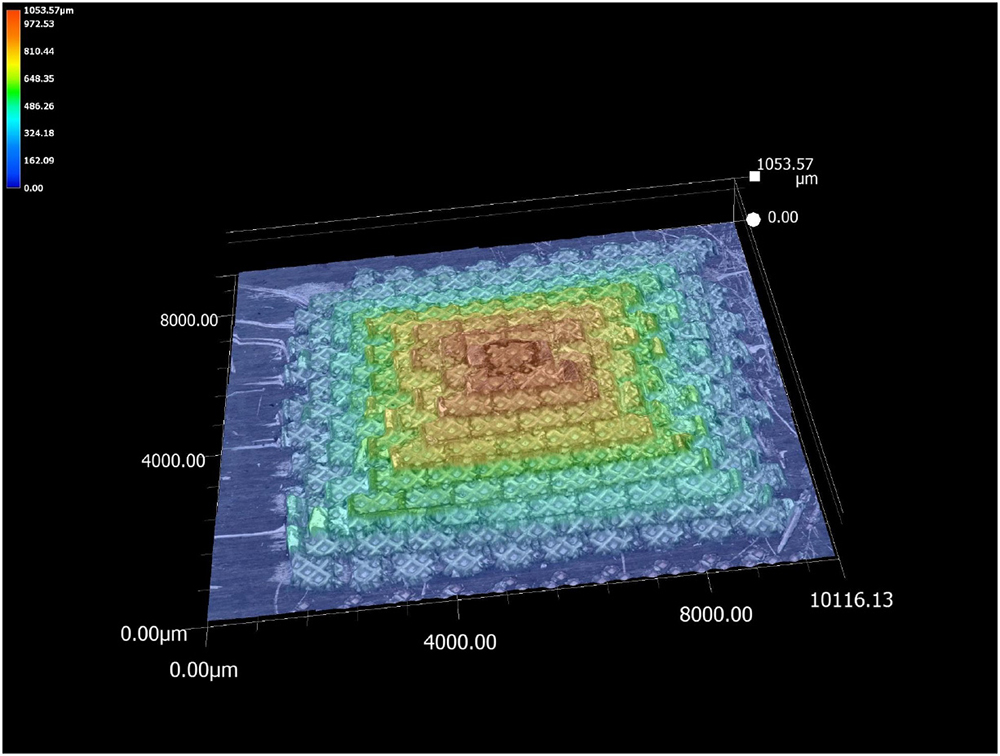

A new solid-state metal additive manufacturing technology is developed based on scalable multi-material ultrasonic AM (SMAM) without a melting or liquefying process.

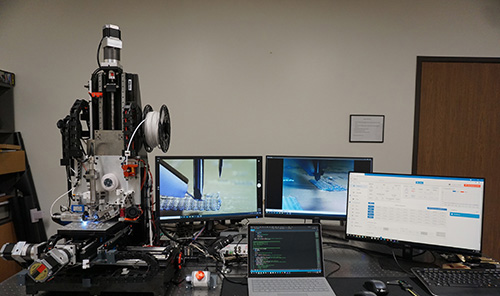

Interlog’s Composite-Material Matrix Rapid Prototyping System (CMRPS) provides a unique multi-material / composite material additive manufacturing (AM) capability with a model validation interface: The CMRPS system utilizes a modular multi-function printer head (MPH) based on Interlog’s AM technology to build composite material parts (e.g., polymeric composites and metal-matrix as well as metals and polymers). The CMRPS is interfaced with a computer-aided design (CAD) tool and finite element analysis (FEA) simulation package software. For validation and verification (V&V) capability, CMRPS has metrology / NDE (non-destructive evaluation) submodules integrated onto the MPH unit.

Interlog’s Additive Manufacturing Technology

Founded in 1992, Interlog Corporation specialized in the fabrication of quality electrical and mechanical components for use on military and commercial vehicles.

1295 N. Knollwood Cir.

Anaheim, CA 92801

1-714-529-7808

info@interlogcorp.com

Our products include vehicular lights, signal components, electrical assemblies, wiring harnesses and other precision-fabricated components. Our commitments to high standards are demonstrated by the superior products and exceptional service we provide to our customers.

ISO 9001:2015 Certified Quality Management System

Additive Manufacturing

Solid State Metal 3D Printing

CMRPS Platform

Hybrid Metal Additive Manufacturing

Fully Automatic Ultrasonic Bonding

Noise Control

Noise/Signature Control for Small Caliber Rifles

Isolated Acoustic Cancellation (IAC)

Acoustic Anechoic Chamber and Noise Measurement Setup

Numerical Simulations of a Projectile