Additive Manufacturing

Hybrid Metal Additive Manufacturing

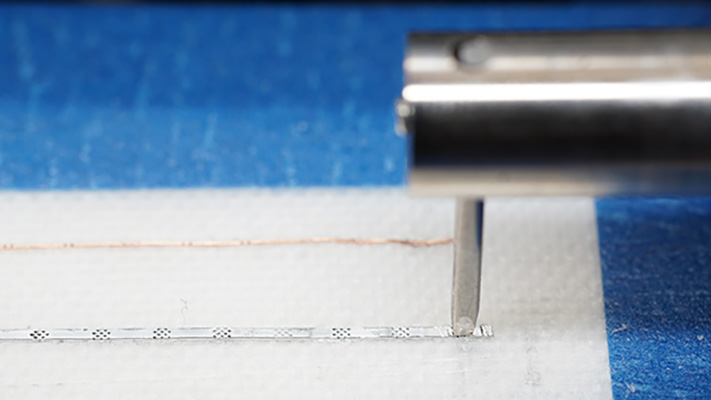

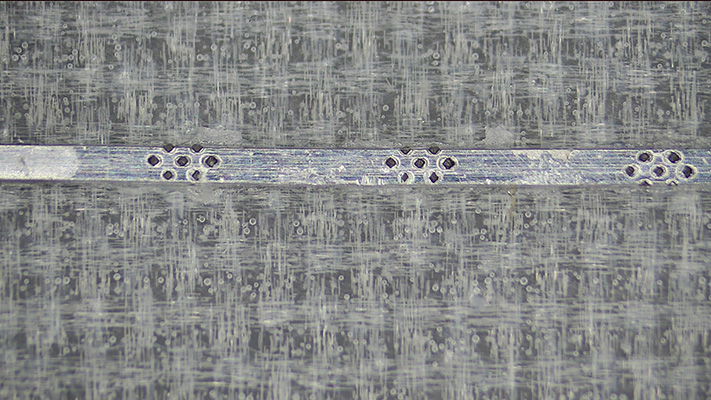

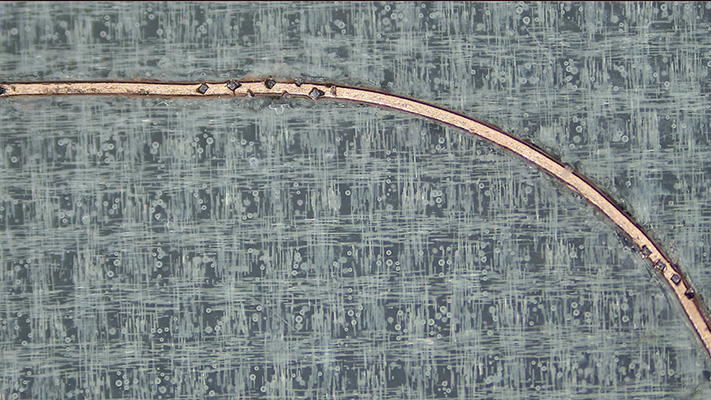

The key feature of our AM technology is solid-state SMAM that uses high-intensity, focused, ultrasonic energy to bond dissimilar materials through instantaneous atomic diffusion without a melting or liquefying process. Our technology is scalable; the dimensions of a single point (or voxel) can be fine-tuned from the micron to centimeter-scale, depending on target applications. Our product's capability of voxel-by-voxel or strip-by-stripe bonding of dissimilar materials (e.g., copper foil on a polymer) has prompted us to develop a new PCB AM technology.

Founded in 1992, Interlog Corporation specialized in the fabrication of quality electrical and mechanical components for use on military and commercial vehicles.

1295 N. Knollwood Cir.

Anaheim, CA 92801

1-714-529-7808

info@interlogcorp.com

Our products include vehicular lights, signal components, electrical assemblies, wiring harnesses and other precision-fabricated components. Our commitments to high standards are demonstrated by the superior products and exceptional service we provide to our customers.

ISO 9001:2015 Certified Quality Management System

Additive Manufacturing

Solid State Metal 3D Printing

CMRPS Platform

Hybrid Metal Additive Manufacturing

Fully Automatic Ultrasonic Bonding

Noise Control

Noise/Signature Control for Small Caliber Rifles

Isolated Acoustic Cancellation (IAC)

Acoustic Anechoic Chamber and Noise Measurement Setup

Numerical Simulations of a Projectile